High Frequency Welded with Multiple Arrow Segment Diamond Grinding Tools Concrete Floor Diamond Grinding Cup Wheel Abrasive Disc

When it comes to floor surface preparation on concrete, granite, marble, or terrazzo, contractors need a tool that’s tough enough for aggressive stock remova. High-Frequency Welded Turbo Arrow-Segment Diamond Cup Wheel delivers unmatched versatility, combining high-strength metallurgical bonding, optimized segment geometry, and multi-stage performance.

Price : 9.68-17.08USD

- Information

- Description

|

Product Name |

High-Frequency Welded Arrow Segments Diamond Grinding Cup Wheel Removes Paint, Epoxy & Level Concrete Fast |

|

Diameter |

4inch/4.5inch/5inch/7inch |

|

Bore |

22.23mm |

|

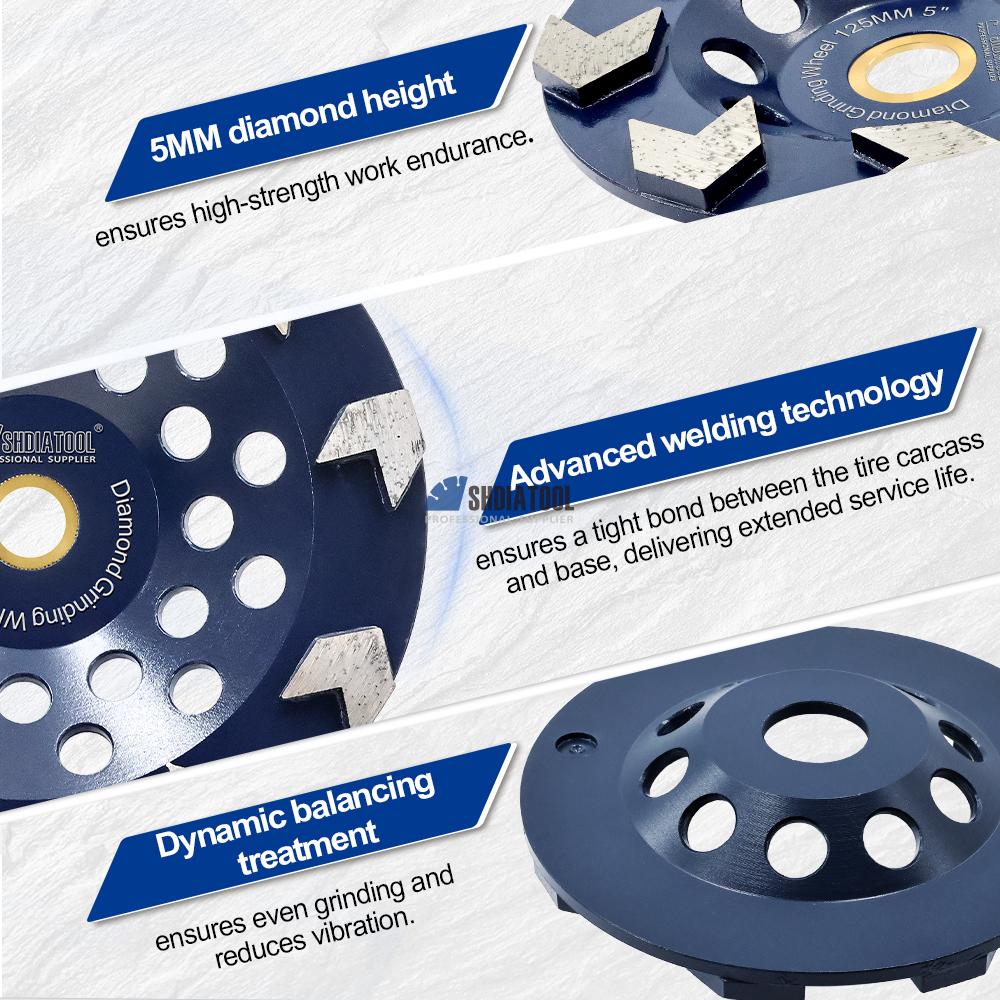

Segment Thickness |

5mm |

|

Grits |

#30/40 |

|

Application |

Mainly for grinding, also can be used to process the special-shaped type material, such as stone material, floor tile. Also can be used for marble, concrete, cement floor, terrazzo, artificial stone , glazed Brick ,rain-damaged concrete and semi-polished concrete |

|

Feature |

1. Advanced high-frequency welded process, the carcass, the substrate close combination, longer life; 2.Wet and dry use, providing the ultimate cost-effective; 3.Durable Diamond Segments: High-grade industrial diamonds for aggressive grinding and extended tool life.

4.Strong Bond Formula: high-quality diamond combain with excellent bond,which specialized design for very aggresive, high-performance, long life grinding tools 7.Customizable Options: Segment shape, grit size, bond hardness, and color available for customization. |

Product Overview

Unlike traditional brazed or sintered cup wheels, this wheel uses advanced high-frequency induction welding to permanently fuse diamond segments to the steel body. This creates: Superior segment retention under heavy load and high RPM Resistance to segment loss even when grinding over rebar or aggregate Excellent heat dissipation during continuous dry operation The innovative Turbo Arrow-Segment design features curved, staggered segments arranged in an “Arrow” flow pattern. This not only increases the active grinding surface but also enhances dust extraction, cooling, and slurry discharge—reducing clogging and improving operator visibility. Whether you’re removing coatings, this HF-welded cup wheel adapts to every phase of your project. Compatible with **angle grinders **(105mm-180mm), planetary floor machines, and ride-on grinders.

Key Features & Benefits:

1.HF High-Frequency Welded Segments

→ Stronger than laser or silver brazing—ideal for heavy-duty concrete and stone grinding.

2.Turbo Arrow-Segment Geometry

→ Curved, staggered layout improves airflow, reduces vibration, and extends service life.

3.Multi-Material Performance

→ Works on concrete, granite, marble, terrazzo, quartzite, and epoxy-coated floors.

|

Product Name |

High-Frequency Welded Arrow Segments Diamond Grinding Cup Wheel Removes Paint, Epoxy & Level Concrete Fast |

|

Diameter |

4inch/4.5inch/5inch/7inch |

|

Bore |

22.23mm |

|

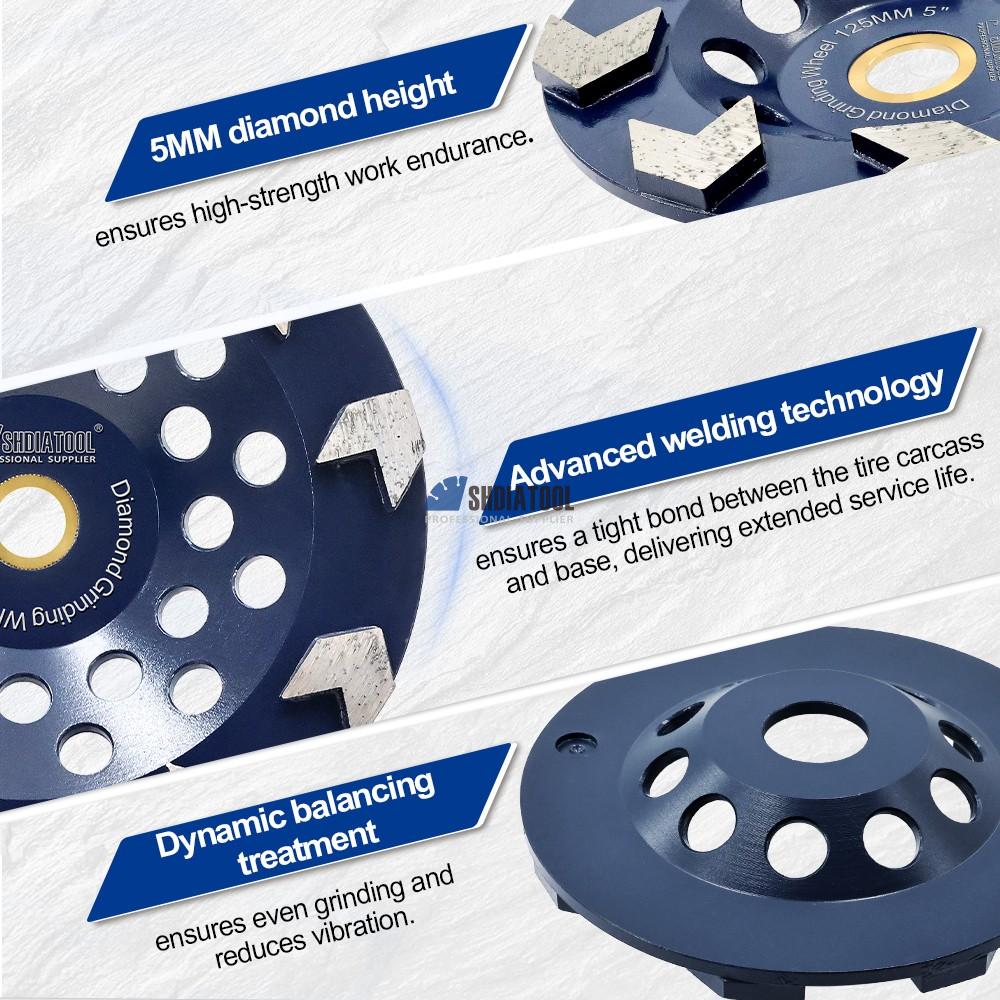

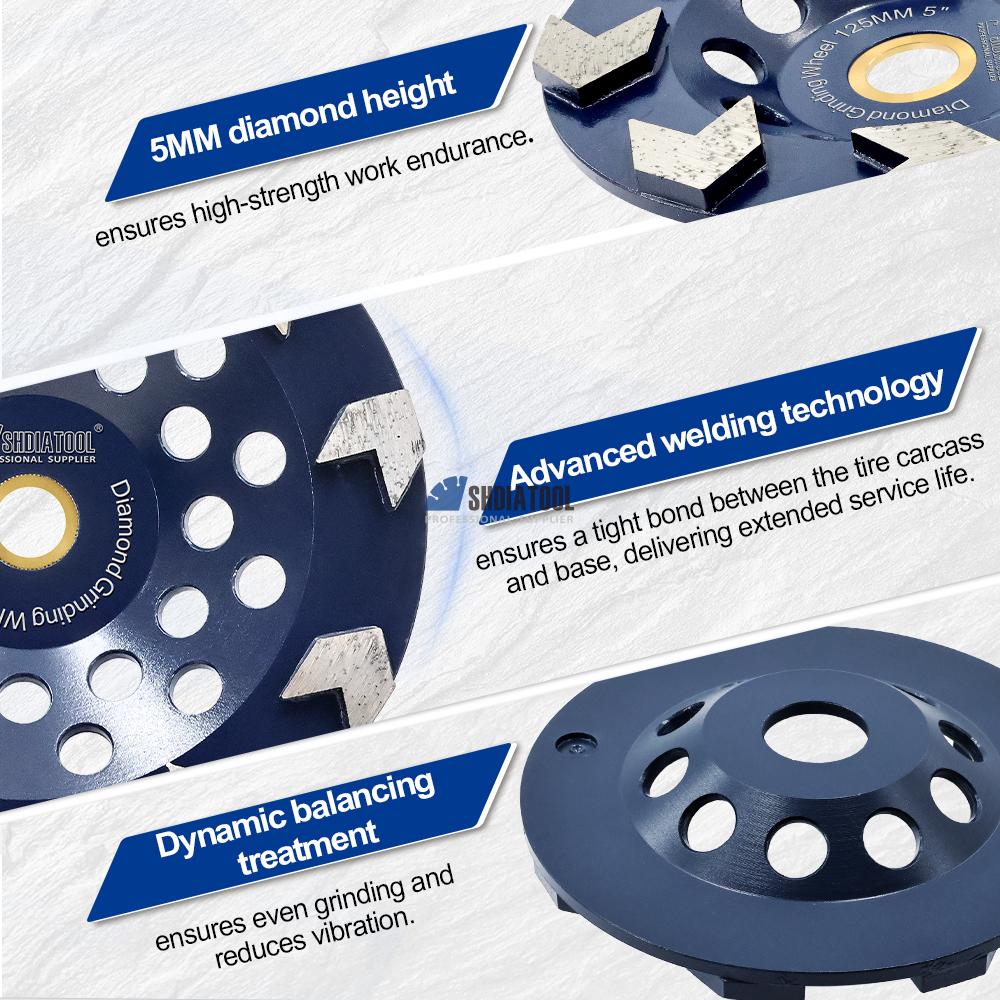

Segment Thickness |

5mm |

|

Grits |

#30/40 |

|

Application |

Mainly for grinding, also can be used to process the special-shaped type material, such as stone material, floor tile. Also can be used for marble, concrete, cement floor, terrazzo, artificial stone , glazed Brick ,rain-damaged concrete and semi-polished concrete |

|

Feature |

1. Advanced high-frequency welded process, the carcass, the substrate close combination, longer life; 2.Wet and dry use, providing the ultimate cost-effective; 3.Durable Diamond Segments: High-grade industrial diamonds for aggressive grinding and extended tool life.

4.Strong Bond Formula: high-quality diamond combain with excellent bond,which specialized design for very aggresive, high-performance, long life grinding tools 7.Customizable Options: Segment shape, grit size, bond hardness, and color available for customization. |

Product Overview

Unlike traditional brazed or sintered cup wheels, this wheel uses advanced high-frequency induction welding to permanently fuse diamond segments to the steel body. This creates: Superior segment retention under heavy load and high RPM Resistance to segment loss even when grinding over rebar or aggregate Excellent heat dissipation during continuous dry operation The innovative Turbo Arrow-Segment design features curved, staggered segments arranged in an “Arrow” flow pattern. This not only increases the active grinding surface but also enhances dust extraction, cooling, and slurry discharge—reducing clogging and improving operator visibility. Whether you’re removing coatings, this HF-welded cup wheel adapts to every phase of your project. Compatible with **angle grinders **(105mm-180mm), planetary floor machines, and ride-on grinders.

Key Features & Benefits:

1.HF High-Frequency Welded Segments

→ Stronger than laser or silver brazing—ideal for heavy-duty concrete and stone grinding.

2.Turbo Arrow-Segment Geometry

→ Curved, staggered layout improves airflow, reduces vibration, and extends service life.

3.Multi-Material Performance

→ Works on concrete, granite, marble, terrazzo, quartzite, and epoxy-coated floors.